AEROLEAD® ANALYZERS

Rapid, Automated Sampling and Analysis of Airborne Lead for Environmental and Occupational Safety Applications

EROLEAD® IS AN INNOVATIVE, LOW-COST RISK MANAGEMENT TOOL

"The AeroLead® Platform represents our commitment to addressing worldwide air pollution issues by providing rapid data to help companies protect people & the environment against heavy metal poisoning."

- Vastly Improved Worker Safety & Production

- Validation of Environmental Emissions Compliance

- Proactive Risk Management for Industry

- Better Community Relations

- Streamlined Environmental Management for Government

Our Objective is to Provide the Analytical Framework to Support Consistent Environmental

& Worker Safety Standards Across the Globe

Portable Automated Airborne Lead Analyzer

AeroLead® 1200

Introduction

The AeroLead® 1200 Portable Analyzer automatically samples, extracts, and quantifies the

concentration of total lead in air. Compliance with environmental and occupational health

regulations can be easily determined, with sample results available in 7 minutes. The total

sampling and analysis cost using the AeroLead® 1200 is less than 1% of typical sampling and

off-site laboratory analysis costs, providing a very short capital investment payback period.

Data from the AeroLead® 1200 Analyzer provides a defensible basis to validate compliance with

occupational and environmental regulations, preventing unnecessary human and environmental

exposure. In short, no one will have better, more rapidly available data than the operator of

the AeroLead®. The quick 7 minute sample turn-around provides the unique capability to rapidly

screen an operational environment to determine locations and/or times when risk of excessive

exposure to lead levels exists. This capability can be used to quantitatively determine the need

for continuous monitoring as required by regulations such as the General Industry Standard for

Lead (29CFR1910.1025) or local environmental requirements

An autocalibration option is available, and full QA/QC support is available. Air sample times

are input by the user according to individual requirements, and can range from 10 minutes to 24

hours. Data output are reported in ug/m3 or ug/filter, dependent upon sample source (ambient air

or personal breathing zone filter cartridge, respectively).

Operational Description

Air samples are automatically drawn or manually introduced through a proprietary sample

filter/detector assembly. The airborne metals are then ultrasonically extracted and concentrated

into a specially designed aqueous phase and analyzed voltammetrically. An integrated airflow

meter is used to determine air sample volume and combined with the voltammetric data to yield

accurate airborne lead concentration in ug total metal per cubic meter of air. The instrument

then automatically cleans and resets for the next sample.

Maintenance and operational requirements consist primarily of simple, periodic replacement of

extraction syringes and sample filters, and less frequent replacement of electrodes and

regeneration modules.

Features & Specifications

Ambient Air Monitoring and Personal Filter CartridgeAnalysis Capabilities

Both Automated Continuous and On-DemandAnalysis

Simple, menu-driven operation

Sample results in 7 minutes

User-Selectable Measurement Range

-

Standard range 0.05 ug/m3 to 500 ug/m3

-

Automatic Baseline & Drift Correction

Sample Flow Rate 1.2-6 L/min

Detection Limit- User selectable

-

LoQ 0.05 ug/m3 standard as shipped

-

Linearity ±3% at 10 ug/m3

Precision typically 4-8% rsd

Interferences: below LDL, except thallium positiveinterference

Total sampling and analysis costs less than $1 per sample

Significantly lowers regulatory compliance costscompared to XRF or lab methods such as NIOSH 7082

Autocalibration option available

QA/QC protocols available

Power Requirements 110 VAC/240 VAC/12 VDC

-

Input 12VDC, 2 Amp regulated orunregulated

-

Output: Digital Display, RS-232C, and USB

-

Weight 24 lb

Dimensions 9” W x 11.5” H x 13” D

Wall-mounted Automated Airborne Lead Analyzer

AeroLead® 2000

Introduction

The AeroLead® 2000 Wall-Mounted Analyzer automatically samples, extracts, and quantifies the

concentration of total lead in air. Compliance with environmental and occupational health

regulations can be easily determined, with sample results available in 7 minutes. The total

sampling and analysis cost using the AeroLead® 2000 is less than 1% of typical off-site

laboratory analysis costs alone, providing a very short capital investment payback period.

Data from the AeroLead® 2000 Analyzer provides a defensible basis to validate compliance with

occupational and environmental regulations, and help prevent unnecessary human and environmental

exposure. In short, no one will have better, more rapidly available data than the operator of

the AeroLead®.The quick 7 minute sample turn-around provides a near-continuous method to monitor

ambient air in locations where risk of excessive exposure to or emission of airborne lead

exists. The instrument provides on-site monitoring to assist in compliance with regulations such

as the General Industry Standard for Lead (29CFR1910.1025) numerous local environmental

requirements.

Air sample times are input by the user according to individual requirements, and can range from

10 minutes to 24 hours. Data output are reported in ug/m3 or ug/filter, dependent upon sample

source (ambient air or personal breathing zone filter cartridge, respectively). An

Autocalibration option is available, and full QA/QC support is available. Up to 20 air samples

can be automatically collected and analyzed; extended operation beyond the 20 sample limit is

provided as an option for applications where longer periods between operator input is desired.

Data can be downloaded to PCs using the optional LeadReport™ software, which provides

pre-formatted data reports as well as the ability to accumulate and manage data according to

operator or regulatory requirements. Data acquisition can be performed either on-command or

automatically, via RS-232C, USB, or wireless data transmission protocols. Cloud-based and VPN

Platforms designed to user requirements are available.

Operational Description

Air samples are automatically drawn or manually introduced through a proprietary sample

filter/detector assembly. The airborne metals are then ultrasonically extracted and concentrated

into a specially designed aqueous phase and analyzed voltammetrically. An integrated airflow meter

is used to determine air sample volume and combined with the voltammetric data to yield accurate

airborne lead concentration in ug total metal per cubic meter of air. The instrument then

automatically cleans and resets for the next sample.

Maintenance and operational requirements consist primarily of simple, periodic replacement of

extraction syringes and sample filters, and less frequent replacement of electrodes and regeneration

modules.

Features & Specifications

Ambient Air Monitoring and Personal Filter CartridgeAnalysis Capabilities

Both Automated Continuous and On-DemandAnalysis

Simple, menu-driven operation

Sample results in 7 minutes

User-Selectable Measurement Range

-

Standard range 0.05 ug/m3 to 500 ug/m3

-

Automatic Baseline & Drift Correction

Sample Flow Rate 1.2-6 L/min

Detection Limit- User selectable

-

LoQ 0.05 ug/m3 standard as shipped

-

Linearity ±3% at 10 ug/m3

Precision typically 4-8% rsd

Interferences: below LDL, except thallium positiveinterference

Total sampling and analysis costs less than $1 per sample

Significantly lowers regulatory compliance costscompared to XRF or lab methods such as NIOSH 7082

Autocalibration option available

QA/QC protocols available

Power Requirements 110 VAC/240 VAC/12 VDC

-

Input 12VDC, 2 Amp regulated orunregulated

-

Output: Digital Display, RS-232C, and USB

-

Weight 24 lb

Dimensions 16” W x 16” H x 9” D

Multi-Metals Continuous Emissions Monitor

AeroLead® 3000

Introduction

The AeroLead® 3000 Analyzer automatically samples, extracts, and quantifies the concentration of

total lead in air. Air samples can be automatically collected and analyzed between calibrations,

with user-defined air sample times ranging from 10minutes to 20 hours. Compliance with

environmental and occupational regulations can be easily determined, with sample results

available in 7 minutes. The total sampling and analysis cost using the AeroLead® 3000 is less

than 1% of typical off-site laboratory analysis costs alone, providing a very short capital

investment payback period.

Data from the AeroLead® 3000 Analyzer provides a defensible basis to validate compliance with

occupational and environmental regulations, preventing unnecessary human and environmental

exposure. In short, no one will have better, more timely data than the operator of the

AeroLead®. The 7 minute sample turn-around provides rapid data to assist process operators in

maintaining lead levels below action levels, and can provide a previously unavailable method to

control fugitive emissions and employee exposure.

Workers of all skill levels can operate the AeroLead® 3000 Analyzer. The operation is simple

(using the menu-driven keypad) and does not require specialized training, nuclear materials or

operator certification. Data can be downloaded via USB or RS232C to an automated data

acquisition system, a PC or laptop computer, making compilation and reporting of data quick,

easy and efficient, resulting in much more effective utilization occupational safety and health

resources. Comprehensive data analysis and regional environmental monitoring can be supported

via VPN near-real-time data telemetry and Cloud-based Platforms.

Operational Description

Air samples are automatically drawn or manually introduced through a proprietary sample

filter/detector assembly. The airborne metals are then ultrasonically extracted and concentrated

into a specially designed aqueous phase and analyzed voltammetrically. An integrated airflow meter

is used to determine air sample volume and combined with the voltammetric data to yield accurate

airborne lead concentration in ug total metal per cubic meter of air. The instrument then

automatically cleans and resets for the next sample.

Maintenance and operational requirements consist primarily of simple, periodic replacement of

extraction syringes and sample filters, and less frequent replacement of electrodes and regeneration

modules.

Features & Specifications

Automated or On-Demand Analysis

Measurement Method Ultrasonic Extraction and AnodicStripping Voltammetry

Simple, menu-driven operation

Sample results in 10 minutes

User-Selectable Measurement Range

-

Standard range 0.05 ug/m3 to 1000 ug/m3

-

Automatic Baseline & Drift Correction

Sample Flow Rate 1.2-6 L/min

Detection Limit- User selectable

-

LoQ 0.05 ug/m3 standard as shipped

-

Linearity 0.05 to 100 ug/m3

Precision typically 4-8% rsd

Ambient Air, PBZ and/or Emissions Monitoring

Total sampling and analysis costs less than $1 per sample

Significantly lowers regulatory compliance costscompared to XRF or lab methods such as NIOSH 7082

Autocalibration option available

QA/QC protocols available

Power Requirements 110 VAC/240 VAC/12 VDC

-

Input 12VDC, 2 Amp regulated orunregulated

-

Output: Digital Display, RS-232C, and USB

-

Weight 24-48 lb

Dimensions 16” W x 16” H x 9” D

AeroLead Applications

Environmental

- Ambient Air Monitoring

- Continuous Emissions Monitoring

Worker Safety and Health

- Ambient Air Monitoring

- Rapid Personal Breathing Zone Filter Cartridge Analysis

- Point-Source Pollution Identification

Industries

- Automotive Supply Chain

- Lead-Acid Battery Manufacturing & Recycling

- Lighting Manufacture

- Metals Processing and Finishing Industries

- Mining & Smelting

- Petroleum

- Lead-Based Paint Abatement

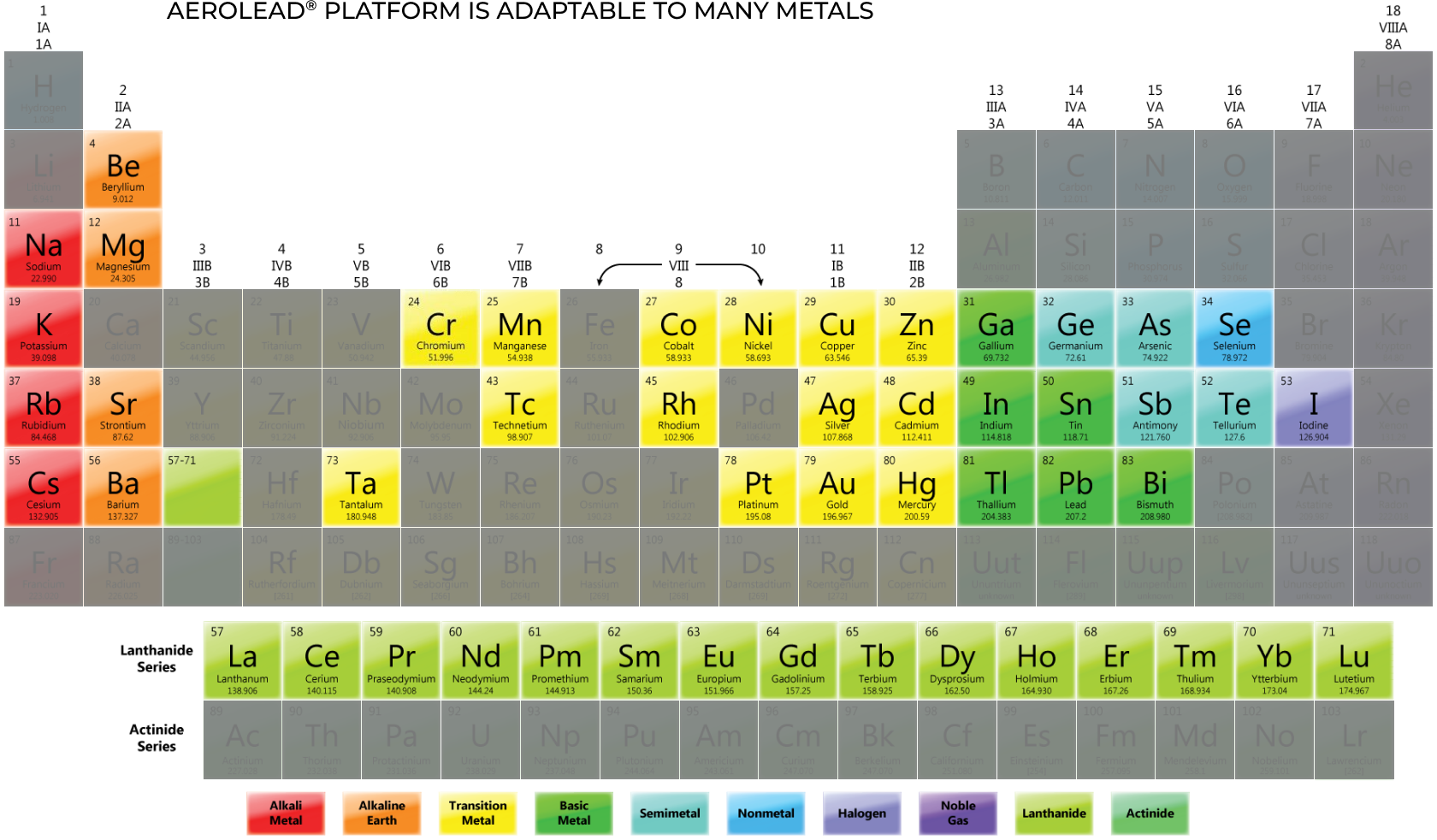

Multi-Metal Analysis Available

- Lead, Cadmium

- Copper, Zinc, Nickel

- Arsenic, Selenium, Mercury

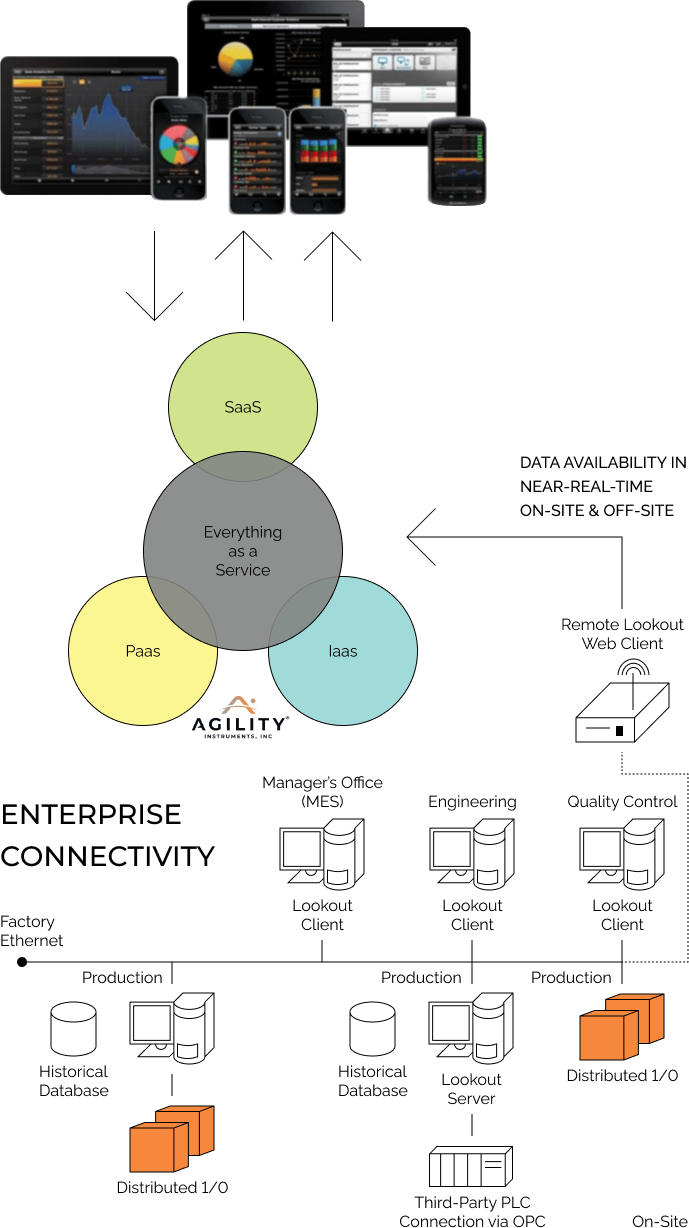

Cloud-Integrated Data Acquisition and Control System

AeroDACS™ Airborne Metals Monitor

Overview

Agility Instruments, Inc. offers a fully integrated data acquisition and control system

(AeroDACS™) designed for any of our AeroLead® line of airborne metals analyzer systems. The software allows

for continuous logging of all AeroLead® analyzer outputs, calibration control and tracking and analyzer

status alerts with alarms.

AeroDACS™ also provides a comprehensive set of tools for database management, historical trending, alarm notifications with email and text messaging, plus a powerful reporting solution with complete Microsoft Excel and SQL compatibility. AeroDACS™ also integrates seamlessly with other emissions monitoring equipment including FTIR analyzers, continuous emissions monitoring systems (CEMS), process monitors, sensors, etc. The package includes a custom graphical user interface (GUI) to present the user with easy to understand information and simple operation. AeroDACS™ is a complete, web-enabled HMI/SCADA software package that delivers unparalleled power and ease of use for any application.

The screens can be customized for

any process or emissions monitoring application where the AeroLead® or other analyzer outputs need to be

captured, stored and accessible for future review. Integration with our cloud platform provides

near-real-time data feeds across an entire region or country.

FEATURES AND BENEFITS

- HMI/SCADA software

- Object-based architecture

- Easy networking

- OPC client and server

- Full MODBUS/TCP compatibility

- Industry standard drivers

- Online configuration

- Web control and monitoring

- Database and MES connectivity

- NT service capability

- Distributed alarms and data logging

- Built-in security

- Event-driven processing

- Multi-user client licenses

- Full redundancy option available

- Windows-based operating system

EVENT-DRIVEN PERFORMANCE

- React to events substantially faster than loop-based software

- Poll more than 50,000 I/O points

- Scale your application with little performance loss

Object Developer Toolkit

- Modify the application without interrupting device communications

- Eliminate gaps in data and alarm monitoring

- Develop and modify applications without process downtime

Distributed Logging

- Log and retrieve data from any computer on a network

- Use configuration-based logging tools for instant data logging

- Maintain process history accurately and automatically

Distributed Alarms and Events

- Create an audit trail using event logging

- View and acknow ledge alarms and events from any where ina network

- Alert a pager or cell phone, or play your own voice messages on alarm conditions

- Use the new Historical Data Viewer to better visualize and manage your data

NT Service Capability

- Windows 2000/NT/XP service

- Full functionality independent of login status at workstation

Security

- Lock AeroDACS™ so users cannot close, minimize, or exit once it is operating

- Provide read or write access levels to processes, folders, and objects based on security levels

- Activate security based on IP addresses

- Use the same security setup for all clients, including remoteWeb clients

Network and Connectivity

With AeroDACS™, you can collect real-time information for faster decision making, while providing access to authorized users only. Simply browse and select to connect to any computer in a network. AeroDACS™ uses TCP/IP-based networking technology to instantly view and control I/O points anywhere in the network. In addition, you can both monitor and control your process using a Web browser, without experience in HTML or XML programming.

Integrated Monitoring Solutions

In addition to providing complete data acquisition and management for the Agility Instruments AeroLead® products, the AeroDACS™ software can also be configured to integrate other continuous emissions monitoring systems (CEMS) for compliance or process monitoring. Agility Instruments can provide a total solution for practically any application using Fourier Transform Infrared (FTIR) analyzers such as the Gasmet™ CEMS.

Gasmet™ CEMS can be used for continuous emissions monitoring in metals production, waste

incinerators, cement plants, power plants, etc.. In addition, various process monitoring

applications are also possible. Typically, concentrations of H2O, CO2, CO, SO2, NO, NO2, N2O, HCl,

HF, NH3, O2 and TOC (Total Organic Carbon) are continuously measured with the Gasmet™ CEMS. The

Gasmet™ CEMS has been also certified by TÜV (17th BlmSchV) and MCERTS. It also fulfills the

requirements of QAL 1 according to EN 14181 and EN ISO 14956.

We can also integrate the AeroDACS™ software package to include any other type of analyzer or

process equipment such as non dispersive infrared (NDIR), Chemiluminescent NO/NO2/NOX, paramagnetic

and zirconium oxide O2, stack flow and opacity systems, and many other technologies. The software

can be easily configured for full USEPA compliance or simple process monitoring and reporting

requirements as needed.

Proven Performance

For over 10 years, the AeroDACS™ software engine has been used successfully throughout the emissions monitoring industry for USEPA compliance and process monitoring solutions. With this fully integrated software product, Agility Instruments can provide its customers with an off-the-shelf solution which can be tailored for any ambient or stack based emissions monitoring requirements. Out of the box, AeroDACS™ will meet or exceed all EPA regulatory requirements and can be customized for any other country's emissions monitoring rules and regulations. With AeroDACS™, we can help our customers optimize their AeroLead® data acquisition and reporting operations and provide cost-effective, reliable integration with any other process or emissions monitoring requirements.